Company Advantages

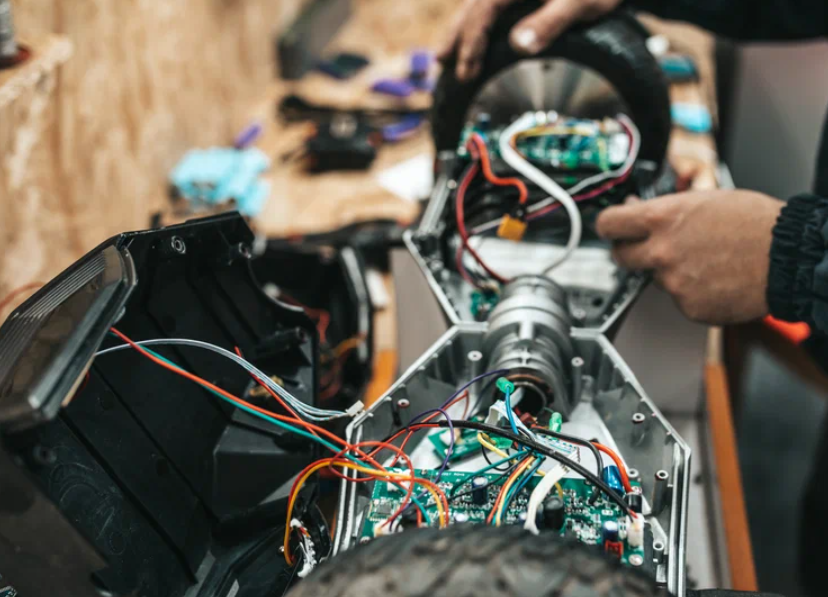

Specialised EV & E-Mobility Expertise

MotoElectric focuses exclusively on electric transport systems: battery chemistry, BMS diagnostics, hub and mid-drive motors, regenerative braking calibrations, and dedicated safety checks. Our technicians receive continuous training on battery handling, firmware updates, and high-voltage safety. This specialisation reduces misdiagnosis, limits downtime, and ensures repairs are done according to manufacturer tolerances and safety standards.

Fleet-Friendly Preventive Maintenance

We design preventive maintenance schedules tailored to usage intensity and climate. For fleet operators, our packages include routine battery health audits, tire and brake cycles, and telemetry-based checks to catch issues before they escalate. Predictive alerts and regular on-site visits keep vehicles moving while optimising maintenance budgets.

Mobile Repair Units & Depot Services

Our mobile vans perform roadside diagnostics and repairs for single units or small clusters, minimising pick-up logistics. For larger fleets we provide depot servicing with dedicated bays, lifting equipment, and climate-controlled battery workspaces to ensure consistent, safe turnarounds.

Transparent Diagnostics & Reporting

Every service includes a clear diagnostic report with measured battery capacity, cell imbalances, error logs, and recommended actions. Fleet managers receive CSV exports, service history timelines, and cost projections so decision-making is simple and auditable.

Genuine Parts & Warranty Support

We source manufacturer-approved replacement parts and offer warranty management for authorized components. Where practical, we fit upgraded parts that improve reliability while documenting changes in the vehicle record for compliance and resale value.

Sustainability & Safe Disposal

MotoElectric adheres to responsible end-of-life practices for batteries and electronic components. We partner with certified recyclers and follow local regulations for hazardous waste, while exploring second-life battery programs to reduce environmental impact.